AntiswayComplete™

Easy Antisway Upgrade

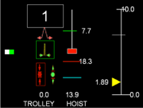

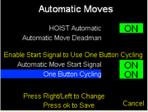

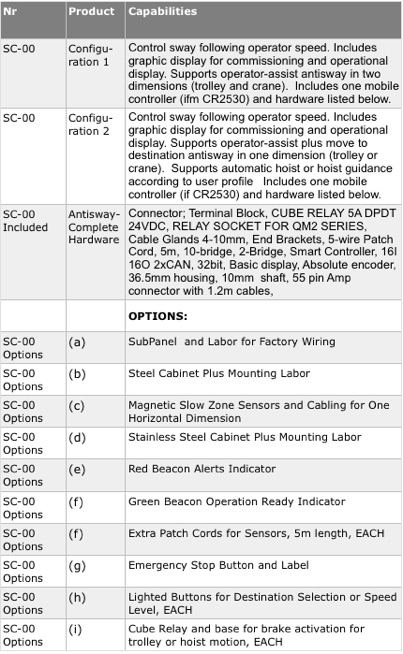

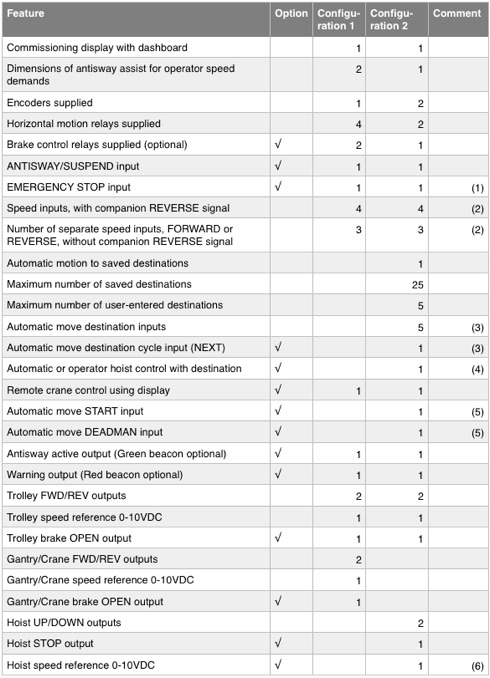

Functions include operator-assist antisway or pushbutton automatic move with up to 25 saved destinations, 5 by the user.

Antisway horizontal motion control requires AC motor with VFD or DC motor and drive with feedback speed control. System applies all ramps; drive ramps should be set at minimum.

Installation and Commissioning

Delivery Options: (1) completely assembled with enclosure, (2) pre-wired and installed onto subpanel, or (3) un-wired kit form. Complete assembly and wiring instructions are included, with unlimited telephone, text, or email assistance.

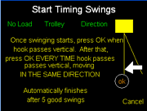

Passcode-protected commissioning is supported with step-by-step instruction screens. System tunes itself for precision moves.

Automatic destinations are easy to record and modify. Absolutely no programming is required.

Low Cost: Introductory kit prices start at less than $3,000US.

Painless Automation

SmartCrane LLC announces the launch of its AntiswayComplete™ product designed specifically for smaller cranes with no PLC or controller.

Upgrade any overhead crane with contactor controls to a safe, efficient, easy-to-use, automated crane with SmartCrane’s hardware and software.

Get the whole system kit, including software, for less than the cost of some popular PLC and HMI combinations!

Call +1.757.303.0167 or

email sales@smartcrane.com for a cost quote today.

©Copyright 2018 by SmartCrane, LLC - All rights reserved.

Inputs, Outputs, and Features

Ordering Guide

-

(1)Automatically detected if wired (must be normally closed). During commissioning select stopping method: with or without antisway (but with ramp time). Could be wired to interrupt power but this is dangerous and not recommended.

-

(2)Set speed inputs to x%, y%, (z%) during commissioning; last one is always 100%.

-

(3)A total of 25 destinations are supported. These may be uploaded from external computer, or up to five of them may be entered by the user in commissioning mode. If “cycle destinations” option is selected, then Automatic move START input signal must be provided and destination 1 becomes the “NEXT” signal.

-

(4)All recorded destinations have defined TRAVEL and DESTINATION hang lengths (square move). Automatic hoist UP/DOWN output option may be set during commissioning. The system will delay trolley motion until correct TRAVEL hang length is reached, by either automatic or operator control.

-

(5)START and DEADMAN can be selected together; if DEADMAN is selected without START, then the DEADMAN signal will trigger the start of moves.