For most PLCs, SmartCrane offers a software library that implements open loop anti-sway plus automatic move to position. Separate licenses required for destination pushbutton handling and closed-loop sway correction using customer-supplied swing measurements.

Software Libraries for PLCs

PLC SOFTWARE FEATURES

SmartCrane™ Anti-sway is computer-controlled operation of trolley and/or gantry speeds for the purpose of reducing or eliminating sway caused by horizontal acceleration. The SmartCrane™ software accepts demand inputs and generates real-time, analog speed references to be supplied to the crane drive(s).

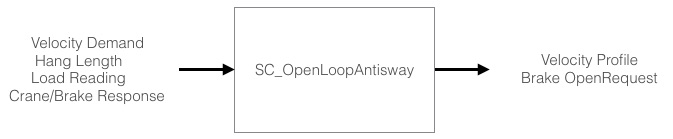

The patented SmartCrane™ Anti-sway Control uses an open-loop algorithm that eliminates load sway induced by trolley accelerations and decelerations. It is contained in one protected software element, called SC_OpenLoopAntisway.

The open loop sway control software responds to velocity demands for one direction of travel and inhibits nearly all added sway in all demand sequences. The open-loop algorithm does not correct existing sway (about which it has no information) but simply preserves the initial sway throughout a movement event. The sway will be the same at the end of a move as it was in the beginning (zero if sway was zero at the start).

The speed demand can be simple on/off for maximum speed or zero, some stepped version, or analog. The demand can be changed repeatedly but, at the end, there will be little or no sway. Speed demand can be supplied by operator or (see below) from SmartCrane’s automatic move software.

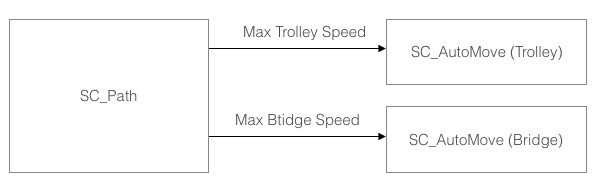

The Automatic Move software, called SC_AutoMove, drives the horizontal speed demand to move from the current position to the supplied destination position, in one dimension. It generates a velocity demand which is passed for execution to the open loop algorithm for sway control.

The algorithm begins by requesting the maximum speed, then switches to zero demand to begin slowing as it approaches the destination. This leaves the open loop software to supply the antisway acceleration and deceleration profiles as required. After the crane has stopped, the automatic move algorithm may then use a very small (“creep”) speed demand, as needed, to move the position into the destination window.

The SC_AutoMove software respects all system constraints such as ramp time and will reach its specified maximum speed only if the distance to be covered is great enough to permit. The SC_AutoMove software, like the SC_OpenLoopAntisway software, operates in just one dimension, independently, and is instantiated separately for bridge and trolley motions.

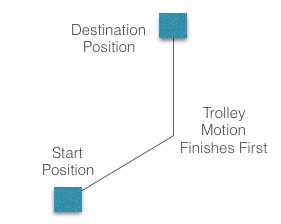

Using the crane design speed limit in each direction, a move from one X-Y position to another, one of the movements will finish before the other, producing the effect of a two-leg move:

The Path Following software, called SC_Path, manages both dimensions of motion at once in order to steer the trolley along a straight path and to have both dimensions of travel arrive nearly simultaneously at their respective destinations.

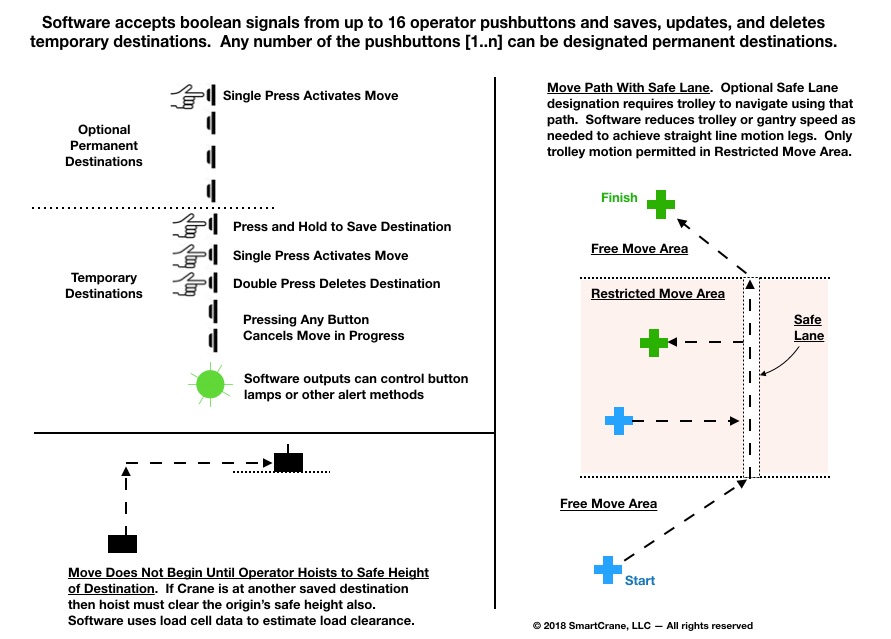

The Destination software, called SC_Routes, allows for the selection of pre-stored destinations as well as safe lane definitions and complex motion paths, in two dimensions. This software inhibits motion for required safe hoist heights and can be configured to produce hoisting and lowering commands automatically.

©Copyright 2021 by SmartCrane, LLC - All rights reserved.